Plasma Spray Coating Process

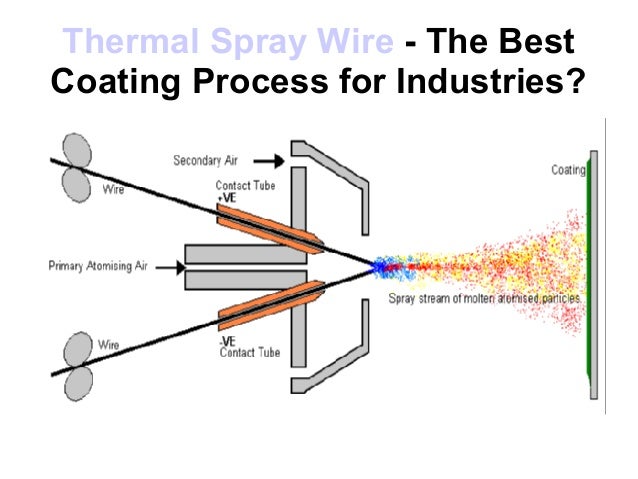

Plasma spray coating process. PSP is an ISO 90012008 certified organization since 2004. FutureThe cold spray process produces dense low oxide coatings which can be used in such diverse applications as corrosion control and metals. Aerospace Medical Marine Electronics Automotive Mechanical Engineering Petrochemical.

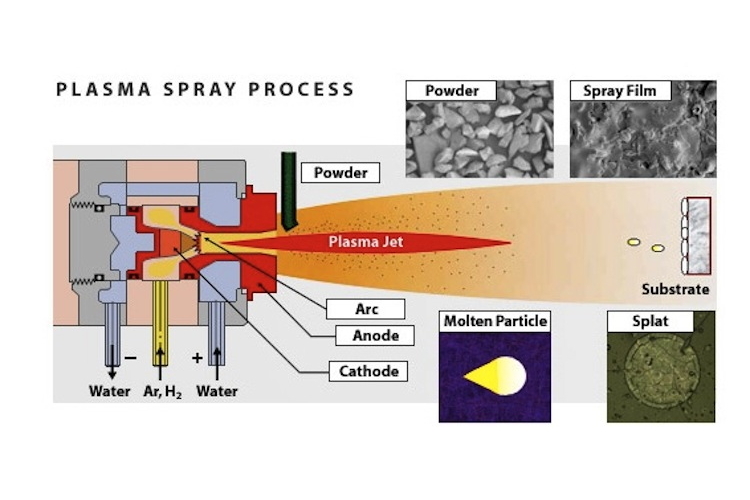

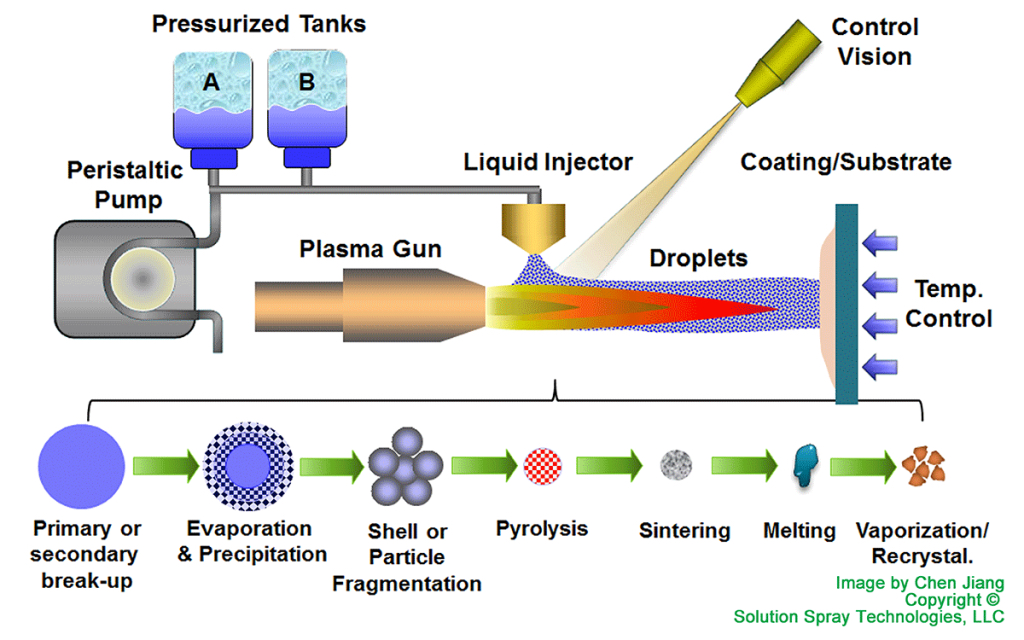

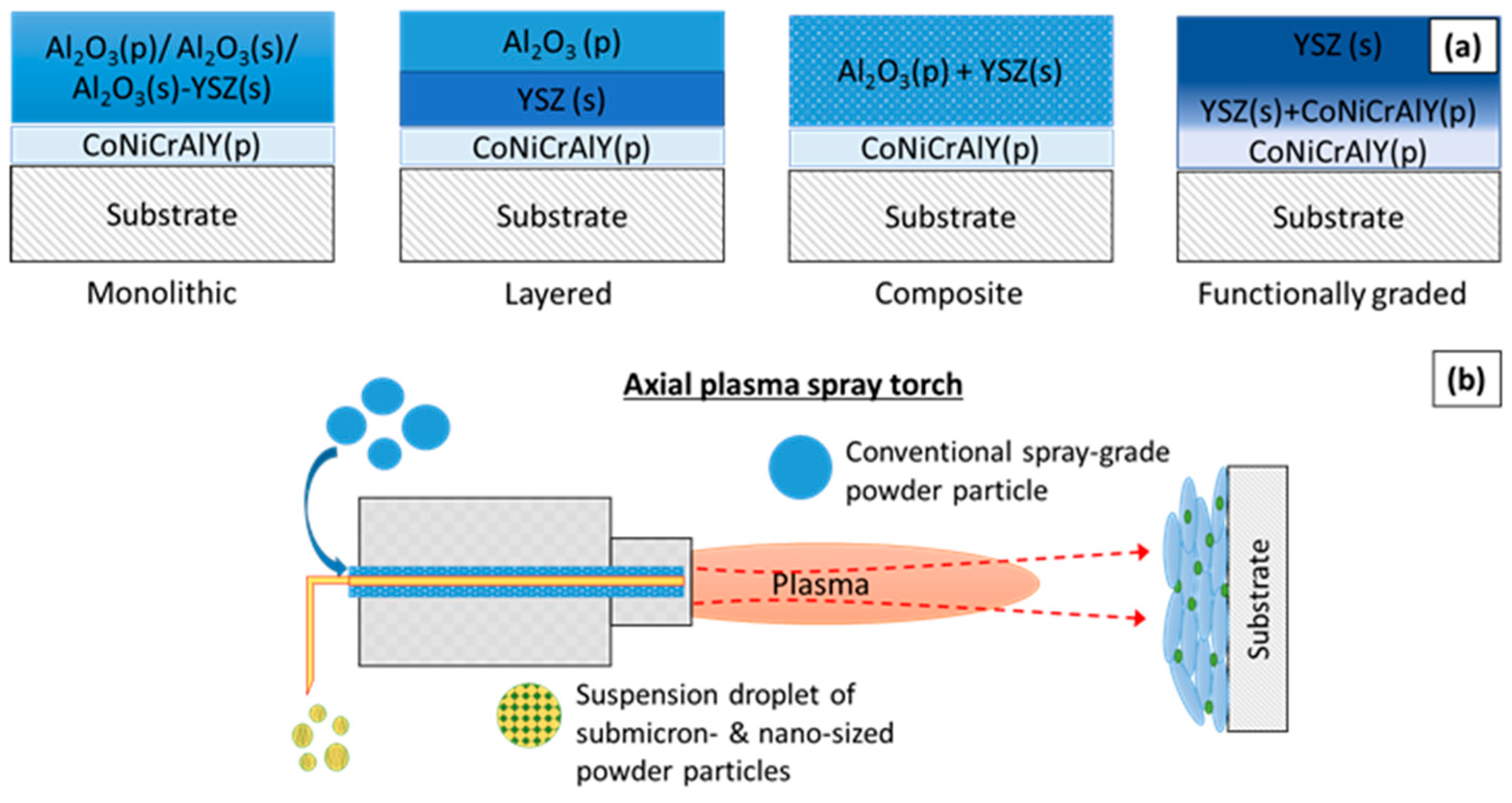

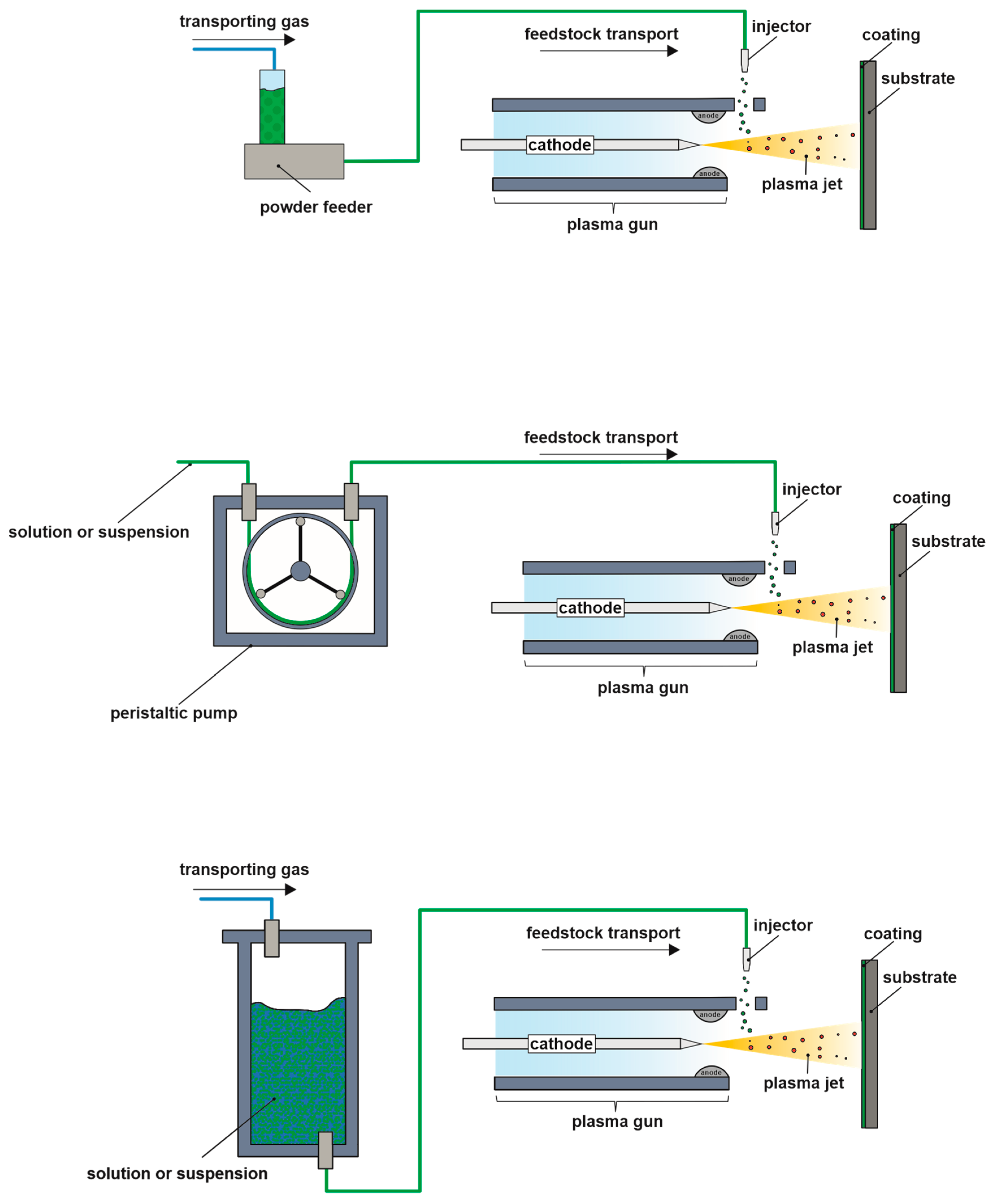

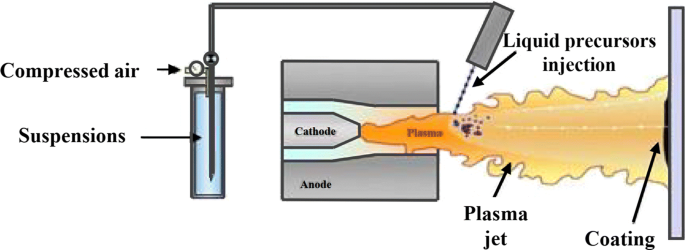

The Process of Plasma Spray Coating As we mentioned before plasma spray involves the spraying of heat-softened or molten material on to a solid material to provide the desired coating. Complete modeling of plasma spray coatings involves modeling of the plasma fields calculating particle trajectories and temperature history and modeling the impact of molten droplets on the substrate and formation of individual splats. It was the first exclusive commercial job shop to be established in India.

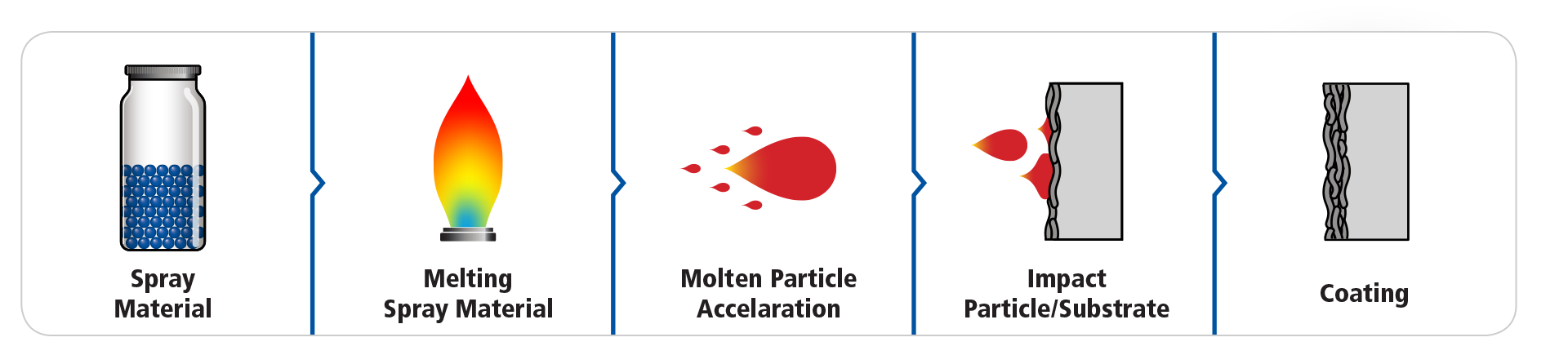

When the plasma spray process cools its called the cold process. The thermal process creates the coating by spraying material in the form of powder into a 14000 K plasma flame. Material in the form of powder is injected into a very high temperature plasma flame where it is rapidly heated and accelerated to a high velocity.

Plasma spraying is a thermal coating process in which particles that have been softened by heat form a coating onto a substrate. The process starts by injecting material in powder-form into an exceedingly hot plasma flame. Up to 2 cash back Plasma-Spray Coating offers a stimulating combination of basic concepts and practical applications.

The process parameters of plasma spraying can be controlled quantitatively the process is stable and the coating has good reproducibility. This process aims to prevent corrosion or damage and allow materials that have been sprayed to last longer and have improved resistance. In plasma spraying the flying speed of particles in molten state can reach 180-480m s or even higher which is much higher than that of particles in oxygen acetylene flame powder spraying of 45-120m s.

Plasma spray coating is a highly versatile process that is used by industries including. Gas is flowed through the plasma spraying system at a selected gas flow rate of about 115-130 Lmin. 9 rows Plasma spraying is a very versatile process since coatings of many material types can be.

Before the HVOF system was invented plasma guns were. Located 50Km away from Mumbai PSP offers Surface Coating and Refurbishment services for components by Thermal Spray Process.

Up to 2 cash back Plasma-Spray Coating offers a stimulating combination of basic concepts and practical applications.

The Plasma Spray Process is basically the spraying of molten or heat softened material onto a surface to provide a coating. This process aims to prevent corrosion or damage and allow materials that have been sprayed to last longer and have improved resistance. Plasma Spray Coating Process The objective of plasma spray coating is to heat up and scatter material particles across the work surface with minimum waste and overspray. Up to 2 cash back Plasma-Spray Coating offers a stimulating combination of basic concepts and practical applications. Materials scientists and engineers as well as graduate students will find this book of enormous. Plasma Spray Processors also known as PSP was established in 1984. Material in the form of powder is injected into a very high temperature plasma flame where it is rapidly heated and accelerated to a high velocity. Plasma spray coating is a highly versatile process that is used by industries including. When the plasma spray process cools its called the cold process.

Up to 2 cash back Plasma-Spray Coating offers a stimulating combination of basic concepts and practical applications. In plasma spraying the flying speed of particles in molten state can reach 180-480m s or even higher which is much higher than that of particles in oxygen acetylene flame powder spraying of 45-120m s. The Process of Plasma Spray Coating As we mentioned before plasma spray involves the spraying of heat-softened or molten material on to a solid material to provide the desired coating. Gas is flowed through the plasma spraying system at a selected gas flow rate of about 115-130 Lmin. PSP is an ISO 90012008 certified organization since 2004. Complete modeling of plasma spray coatings involves modeling of the plasma fields calculating particle trajectories and temperature history and modeling the impact of molten droplets on the substrate and formation of individual splats. FutureThe cold spray process produces dense low oxide coatings which can be used in such diverse applications as corrosion control and metals.

Posting Komentar untuk "Plasma Spray Coating Process"